[email protected] +90 (552) 220 4213

The most effective solution for flexographic printing in short and medium runs

The RASMAK CI FLEXO machine is the reference in this market segment. After its market launch in 2010,

sales have been successful and it is currently being reproduced by various players within the sector.

The RASMAK CI FEXO has been the first to embody the patented FLEXO Efficiency concepts of

ergonomics and accessibility, as well as performance and robustness, which are also characteristics of

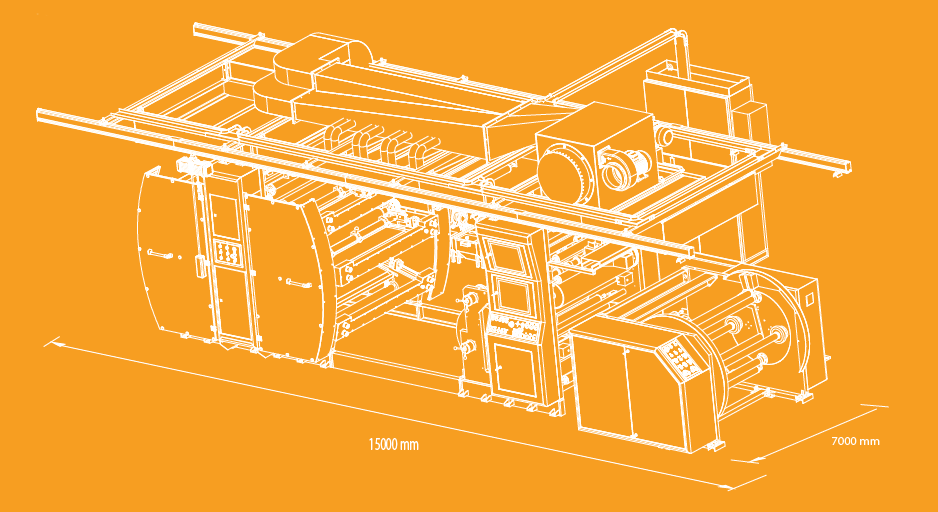

the whole RASMAK machine range. It is the perfect solution thanks to its dimensions that facilitate any

form of handling during the printing process.

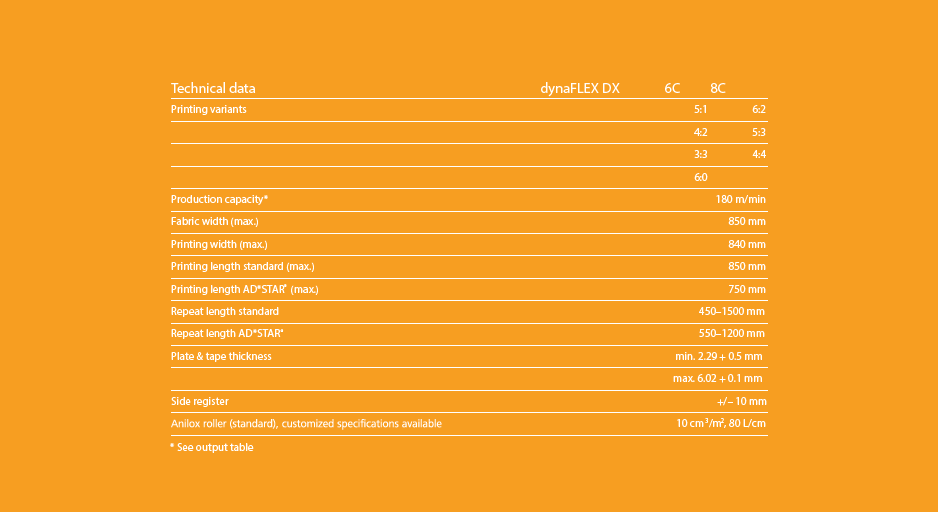

CI FLEXO C6 / C8

Pressure roller: sleeve type

Ceramic anylox: sleeve type

Pneumatically adjusted Doctor Blade system

Ink pump system driven by frequency changable motors

Process adjustments by recipe basis

Limitless process memory registering possibility

Drying system with frequency changable drives,

Position register adjustment sidewise with automatic servo motor unit

Position register adjustment lengthwise with automatic servo motor unit

Bobbin changing at high speeds with non-stop double turret unwind/rewind system

Automatic material stretch monitoring

Automatic Camberoller type edge control pre print and pre rewindind

Advantages

For special applications the CI FLEXO can be equipped with up to 8 color d.

It’s possible to print on paper ,(LDPE, HDPE,PP,BOPP)